Hacking a stripe into my Weave-Along warp

During the last Weavers’ Talk, someone asked if Carly, Tien and I were all going to jointly demonstrate winding our WAL warps. As fun as that sounds [read: prone to mayhem, never mind mistakes], that wasn’t in the cards for this WAL. Still… I hadn’t wound my own warp yet and, even though I’d covered a couple of really cool warp winding tricks in the lessons for Week Three, there were other things I wanted to share, too.

“What the heck,” I thought to myself. “I’ll record myself winding the warp and explain what I’m doing as I do it! What could go wrong?”

… … … m’yeah. You see where this is headed, I’m sure.

How I screwed up

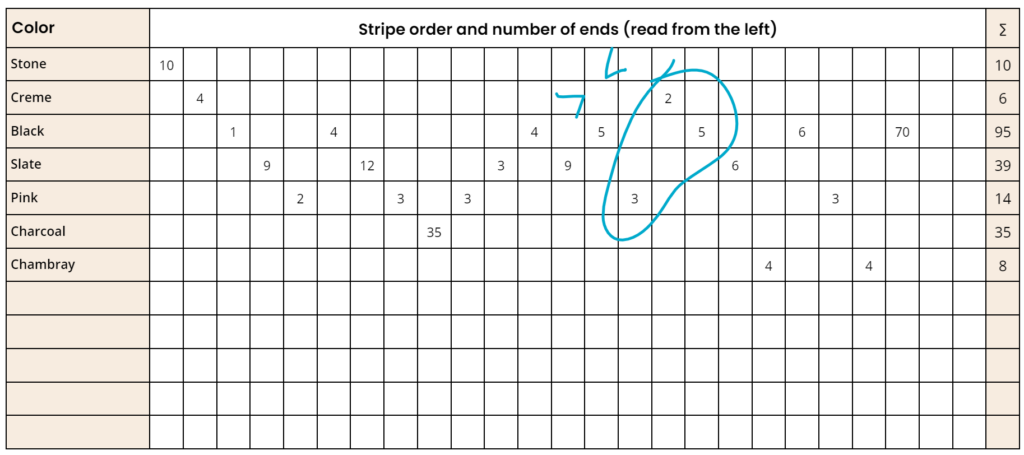

You know how a thing is harder to do when someone is watching? Turns out that applies when you’re recording it for someone to watch later, too. Add being focused on the camera, the lighting, the audio, and what I was saying to the fact that I hadn’t designed the stripes myself so wasn’t as familiar with them as I might have been, and I managed to completely miss three stripes in Tien’s carefully crafted color order.

I didn’t notice that I’d done it until I was threading the warp. I got to a point where the color order chart said I was supposed to have a stripe of three pink ends, but the threads in my hand were black. I looked at the chart. I looked at the threads. No doubt about it: something was missing. When I checked the chart again it was easy to see what had happened: I’d wound the first stripe of five black ends, gotten distracted by something, and then assumed I’d already wound the second stripe of five black ends when I started winding again. As a result, I was missing 10 threads: three pink, two crème, and the second stripe of five black.

As I wound the warp:

As Tien designed it:

I confess: I thought about just weaving the scarf as it was. If it were my project alone, that’s absolutely what I would have done. If no one had seen the design in my mind’s eye, no one would ever know that the scarf was three stripes short!

Still… it wasn’t my design, it was Tien’s. She planned it a certain way and was expecting to see what was in HER mind’s eye. Not to mention the fact that hundreds – possibly thousands! – of others knew exactly what she’d designed, too, ‘cause it was right there in the livestreams and the lessons. There was no way I could pretend those stripes weren’t supposed to be there.

How I fixed it

I was cranky and tired and in a hurry to get things done, so I didn’t want to fix it right then — and wasn’t so sure about fixing it later either, thankyouverymuch. I DID want to finish threading the warp, though, and I didn’t want to eliminate the option of adding in the stripes later after I’d had my snit.

So here’s what I did:

- After the five black ends I did have, I pulled over empty heddles for the 10 threads I didn’t have, on the right shafts to thread them later if I decided to. If I didn’t, the empty heddles wouldn’t hurt anything at all, so no harm done if I wimped out.

- I finished threading the rest of the warp.

- I went to bed and slept on it.

(Note that I hadn’t sleyed the reed yet; if I’d done that too, I would have left empty dents for the missing threads in the reed as well as the empty heddles on the shafts.)

After a night’s sleep, I was far more inclined to put in the little bit of effort required to add those missing stripes back. Besides, I told myself, it was a good opportunity to let others benefit from my mistake. Silk purse from a sow’s ear and all that.

The key was leaving the empty heddles in place for the missing threads. If I hadn’t done that, it would have meant either rethreading half of the warp or creating 10 string heddles, neither of which sounds like much fun. With the heddles already there, all I had to do was wind a wee little chain of the 10 missing ends, then thread them through the heddles and treat them just like the rest of the warp. Not that much more trouble than winding them properly in the first place, really.

Having made my decision, I set up my warping board again and measured out a tiny warp of 10 ends, and then wound those 10 ends onto a “warp stick” (cleverly disguised as the empty core from a spool of cotton):

Then I dropped the stick behind the loom with just a little tension on the threads and threaded those 10 ends through the empty heddles I’d left, making sure I got both the color order and the threading order correct.

At that point I unwound a little more of the warp from the stick so it could sit on the floor – I didn’t want the weight of the core to pull the threads out of the heddles while I worked – and continued dressing the loom as if those ends had always been there. Which is to say, I sleyed the reed and tied onto the front apron rod as usual, treating all of the warp ends the same way.

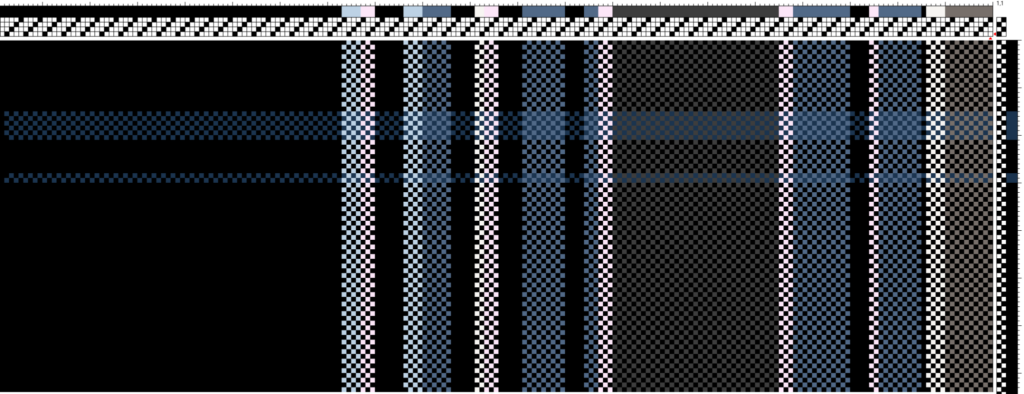

Now I had exactly the warp that Tien had designed, most of which was beamed onto the loom but one section of which was hanging off the back.

Weighting the chain

Once the warp was tied to the front apron rod, it was safe to put more weight on the threads wound onto my wee little warp stick. I made a slip knot out of the whole little warp chain to create a loop, and then hung a shower curtain ring from that loop. From the shower curtain ring, I hung a weight.

Note that I weighted the entire wee chain as a single unit rather than trying to put weight on individual threads: it had been wound as a group and put on the stick as a group and I want it to behave as a group as much as possible to avoid the individual threads getting used up at different rates and getting tangled.

My first guess for how much weight I needed (a one pound exercise weight) was much too heavy, so I replaced it with heavy washers. It took a little bit of Goldilocks fiddling (four washers was too few, six was too many) but I soon found that five washers was just the right amount of weight:

Note that the warp stick is sitting on the floor, not hanging free. That keeps the chain and the weight hanging from it from spinning in the air. I like the shower curtain ring rather than an S hook because it’s a closed system: no hooks to catch on the warp threads that are beamed or the ones hanging down to the warp stick.

Because these ends aren’t beamed, I have to move the weight myself every couple of feet, but that’s not a big deal. I just take the shower curtain ring out of the slip knot, pull out the slip knot, tie a new slip knot close to the floor, and put the shower curtain ring through it. If I was weaving very quickly and for long stretches, I could hang it from a trapeze of some kind so that I wouldn’t have to move it as often, but I’m only weaving in short stints and the warp is just 3 yards long, so I haven’t bothered with that.

The take-away

One take-away from this story is that accidentally skipping some threads when you’re winding a warp isn’t a big deal – you can add them back in. If you discover they’re missing while you’re threading and can leave empty heddles (and dents) ready to receive those ends, it’s actually quite painless.

But here’s another thing:

You can do exactly the same thing if you’re weaving a project and decide you want to change part of your warp.

Say I decided that big black stripe was too monolithic and it ought to have some pink somewhere in the middle. I could cut a few of the black ends, pull them out of their heddles, wind another tiny pink warp and thread it into place. I wouldn’t want to do that in the middle of a scarf (…probably? It might be interesting to have a color change and a tassel somewhere along the scarf length!) but it’s easy to do at the start.

Say I had enough warp on for three scarves, and I wanted to give one of them to someone who hated pink. After weaving the first two, I could take out all the pink ends and replace them with something else.

If you’re taking warp threads OUT in order to put new threads IN, then the heddles and dents are already there, ready for whatever threads come their way. That’s the biggest problem solved before it even exists. All that’s left is keeping your new little chains organized and properly weighted, neither of which is hard to do.